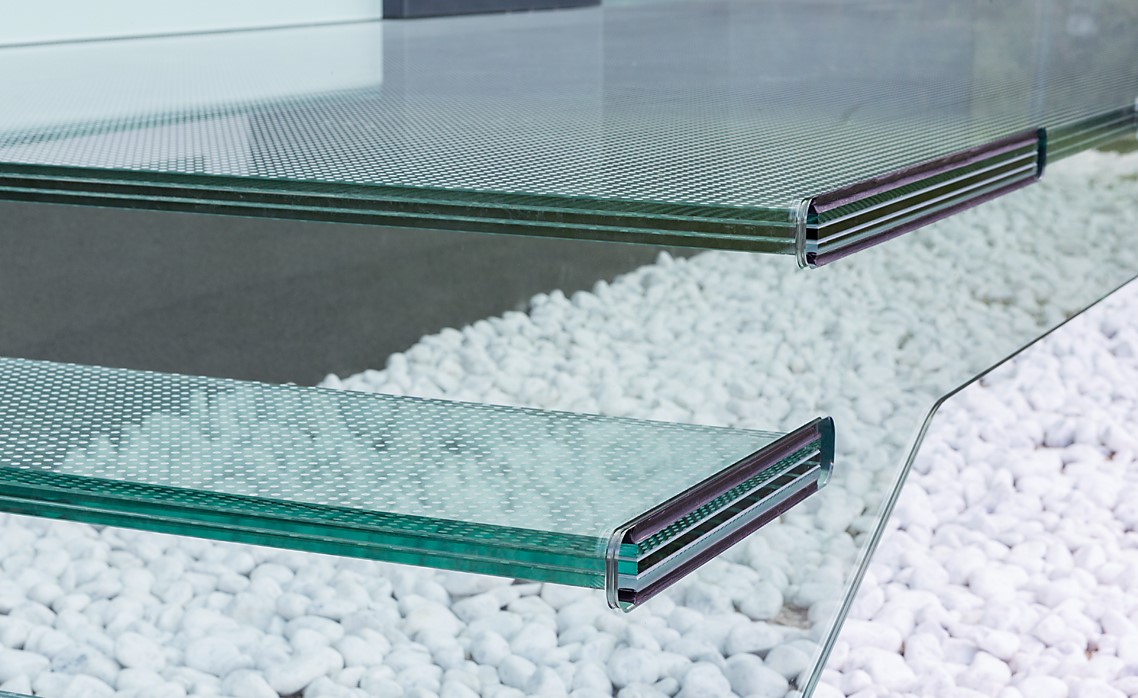

GLASS TEMPERING

Tempered safety glass is produced by heating the glass to a temperature of about 650 degrees Celsius, at which point it begins to soften. The external surfaces are then cooled, rapidly, causing compression. The heating/rapid cooling process is electronically controlled and the individual parameters used during the process influences the final quality of the safety glass giving it a bending strenght of 120-200 N/mm2. Its resistance to mechanical warping is usually four to five times higher than that of normal glass and is appropriately used in cases where it is necessary to mechanically grip the various metal parts attached to the glass

More features

If broken, it fractures into very small, harmless fragments, ensuring the safety and security of people who may come into contact with the broken pieces.

A good tempered glass film can withstand blades, scissors, keys and other hard sharp objects above the ground scraping

Anti-fingerprint and anti-oil